Well tonight the long awaited first drive happened! We pushed the car back and turned it around so we could jack it up and put it on stands to put the CV's back in. While we were pushing it arround, alot of the gearbox oil came out so we had to put more in. Man that stuff stinks like shit! So after that we connected up the rear sway bar and then we were all good to go! Only took it for a short drive on private, closed roads where the car was trailered too as we wouldn't have driven it on a public road ;)

First Drive In The EXA! Sunday, September 13, 2009

Posted by Blake at 9:05 PM 0 comments

Starting The Engine For The First Time Friday, September 11, 2009

After we fixed everything up we went to start the motor for the first time. I wasn’t there so I made sure that Vinnie videoed it and I called him to hear what was going on! First try – nothing :(. Turned out that a plug from the starter motor had come undone. So Vinnie quickly fixed that and then went back to the car for try number 2. Attempt 2 – SUCCESS!!! It took a little while on the starter motor (not ridiculously long) but that was expected because the fuel and oil hadn’t been pumped around the car. We could only use the car and leave it on while the clutch was pressed down the whole time because we haven’t put the CV joints back on yet. The engine run’s beautifully, no lumpyness, idles well, revs great, no smoke, mounts are good as the engine doesn’t shake (only a little movement which is normal). It was stupidly loud because the exhaust is off from the cat back but it’s really awesome that the motor works so well! I went around later and had a nice play haha. I’ll get the video up tomorrow hopefully so you can watch the first start. After the first time it started first time every time really well. We’ll get the CV joints back on soon and take it for its first drive! Everything is going to plan! No photos because my camera died.

Posted by Blake at 10:13 PM 0 comments

A Few Touch Up’s Before Starting the Motor

So we did a few touch ups on the car before we tried to start it for the first time. We got some new bolts for the back engine mounts as well as for the shifter rod. God some new oil and air tubing because there were small cracks in the ones that were already in the car. Put the airbox back in as well as all the tubes coming from it and the vacum lines. We need to get some heat shield for the lines where its breaking off such as the air conditioner line. Topped up the gearbox with gearbox oil (even though the CV’s still aren’t in we could start the motor with the clutch in the whole time so the gearbox wouldn’t turn), topped up all the oil, bled the clutch again one last time to make sure and topped up the clutch fluid and also put 12L of petrol in. So here’s a photo (camera died after I took this one photo) of the engine with some of the new tubing.

Posted by Blake at 6:16 PM 0 comments

Fixing Rear 6x9” Speakers

So we took off the rear 6x9 speaker that we installed last night and we found that the wire that was soldered on to the connection to the speaker (because the connection on the wire didn't fit) had snapped off. The wire that came with the speakers was shit so we bought some thicker gauge wire and soldered it on to the connection and then on to the speaker, tested it and mounted it back in the same place and it all works fine. The speakers sit well in the back and don’t sit out too far. We will have to get some filler to cover in the holes the people before us drilled and the square for the diagonal lined speaker covers. So now that both the rear speakers are mounted that is our whole sound system done and working! It sound good! So that’s another job out of the way!

Posted by Blake at 5:54 PM 0 comments

Installing Rear 6x9” Speakers Thursday, September 10, 2009

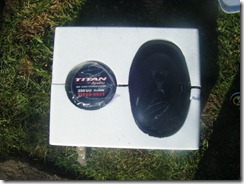

So tonight I started on the rear 6x9” speakers while Vinnie started piecing back the parts of the engine we had to take apart to get to the gearbox etc. The speaker holes are ruined at the back and the mounts that are inside the section are also wrecked. The plastic has been melted away and in the process it made it impossible to install speakers that were stock or the same size as stock so we decided to get some 6X9” speakers and mount them ourselves. There were also holed that had previously been drilled around where the speakers have been which are annoying and we will have to find something to fill them with. So our original idea of making spacers didn’t work because the speaker didn’t allow for much space, it seemed like alot of effort and it would look alot cleaner if we could just mount them normally. So I made a stencil outlining the edge of the speaker, the screw holes for the speaker and where the frame goes back (to make sure there is enough room for the whole speaker to be in the back of the whole and not pop out. After I cut the right size with the dremel, I used some tin snips to cut away at the metal speaker frame and the melted plastic spacer that was behind where the speaker mount was. This sacrificed the stock way of mounting speakers in the rear but because it was already ruined and we had to install 6x9” to cover the mess they made, there wasn’t much lost. After all that was cut away, I soldered on the connections to the speaker as well as to the terminals that were left behind from the previous speaker. These terminals plugged into the connection for the speaker so for the rears, we didn’t have to cut off the stock connections. Then we mounted the speakers by drilling small holes and then screwing the screws into the plastic as well as metal support clips to make the join stronger and hold the speaker in place. By doing all this, it was the best way that we could make sure that if we, or someone else who buys this car wants to change the speakers it will be easy considering how they were.

After we screwed one in we turned on the radio on but the speaker didn’t work :( I called it quits for the night and so I’ll look at it tomorrow and find why there is no sound coming out.

So here’s a few pictures showing what happened and what it looks like now with the 6x9”s. There’s a tiny bit of patching we will have to do just to clean the whole thing up.

Posted by Blake at 9:03 PM 0 comments

Installing Gearbox Wednesday, September 9, 2009

So the same afternoon the gearbox was installed. I couldn’t help because I had to go to work but Tim came and have a hand installing it. Put some new oil in the gearbox but didn’t have enough to fill it so we will get some more tomorrow. So sorry but there are no photos for the installing because I wasn’t there and the rest forgot to take pictures! The gearbox went in with alot less crushing than it did the way out! Geoff made a kind of pulley system that was made from some wood that connected via the struts and a ratchet strap that wrapped around the gearbox, went up over the wooden brace and to an anchor point so it could be lifted easily and guided from underneath. Everything went in nicely and the clutch was aligned perfect the first go! After making sure everything was reconnected we tested out the gearbox by just moving the shifter and it is so good to finally be ably to put the car in a gear! So now its not long to go until we can finally get the car running and take it for its first drive!

Posted by Blake at 8:12 PM 0 comments

Removing the Gearbox and Clutch

Finally today we got the Gearbox out! Originally we thought we could fix it but it was completely wrecked! When we took it out there was chunks of gears all through the box as well as just powdered metal. No oil at all in the gearbox. A bearing casing also busted and a few of the balls had fallen out. Teeth on the differential were chewed and missing and nothing worked at all! The removal was pretty easy, lowering it down was another thing! If you need help replacing it or whatever let me know by email (blake.castle@yahoo.com{) and I'll let you know what we did. It was basically just a whole heap of bolts that connected the gearbox to the motor, as well as disconnecting the starter motor, gearbox mount, speedo cable, ground wire and reverse light sensor. Make sure if you do this to support the engine by placing a jack under the oil pan. Basically the way that we lowered the gearbox instead of using a jack and guiding it down (which would have been alot easier) was to use Vinnie and several blocks of wood! Even though this wasn't the easiest way to get it down it seemed like it would be quicker as we could move it to the side and guide it easier. So Vinnie layed in the pit with blocks of wood on his chest while I undid the last few bolts. Then had a few count downs from three while he held the gearbox up and I took away a plank of wood each time! Not the easiest or smartest way but it got the gearbox off nice and carefully… even though Vinnie got a little crushed! So then we took apart the gearbox to have a look at the damage and yeah it was ruined! So there’s a few pictures of the small pit we made, taking out the gearbox and the inside of it (including gear chunks and powdered metal!)

We also removed the clutch from the flywheel. Well, It wasn’t really a clutch anymore it was completely ruined! We bought the clutch “just in case” and were going to see which clutch would be best to go back in to the car. When we took off the gearbox the first most noticeable thing was the amount of clutch fluff and dust everywhere! It was caught in all of the teeth of the pressure plate and big chunks were just laying around. There was actually no clutch left on the plate and the metal that supports the clutch material showed signs of wear which hinted that even though this clutch was screwed they still tried to use it! So there’s some pictures here of the old clutch, or what was left of it, some clutch fluff, the replacement EXEDY clutch, pressure plate and clutch housing and the new clutch installed.

Next post will be the install of the new gearbox

Posted by Blake at 6:26 AM 0 comments

The Car Is Up On Ramps! Tuesday, September 8, 2009

So finally today we got the EXA up on ramps. We just had to put some wood down at the start of the ramps to give it a bit of lift and then then it went up the ramps no problem. Dug out the pit a little bigger and put some carpet down so now we have a heap of room to play with. Tried to drain the gearbox oil out but… well there was none in there! It would have all fallen out through the cracks and missing chunk in the gearbox. No photos because well its not that exciting! Tomorrow we are going to try and get this gearbox out and get the other one in! Going to be a big day!

Posted by Blake at 6:09 PM 0 comments

Installing Front Speakers Monday, September 7, 2009

Posted by Blake at 8:27 PM 0 comments